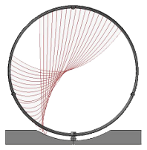

Robotics and Quality Control

Automation, especially in the area of quality control, has dramatically increased. The need for automation integration has also grown. Clients demand ever-better QC reporting, much of it in near-real time.

Catenary Software prefers to focus on test equipment, process control and integration. We do automation consulting and C language realtime coding but integration is where we shine. We can provide standard interfaces for data collection and statistical process control, working with your engineering and manufacturing talent to harvest your QC data and route it properly.

We know comm. Older but perfectly serviceable equipment limited by old RS-232 or IEEE-488 or SCSI interfaces can get a new lease on life with Catenary Software's integration expertise. The standard output of newer equipment can feed robust interfaces which extract useful information and post it where you need it.

There's a dizzying array of vision systems, bed-of-nails board testers, load cells, flying probes, laser measurement systems, laboratory test equipment of all sorts, gas and liquid chromatographs, precision balances, pH assay gear, spectral analysis gear, each with its own interface and data standards out there.

We know how to put on a bunny suit. We know how to consult on a factory floor and in a production laboratory without interfering with your workers. We can observe your processes and create useful applications to improve throughput and quality, working from the ground up, taking direction from the people who know the problems best, your own talent.